ONE STOP to SPALECK

NONSTOP to your customer

Time is money. You can therefore use our

SPALECK ONE STOP Professional Service.

With this, our great vertical range of manufacture and the experience of more than 150 years of mechanical engineering, we are your competent supplier for all aspects of metal processing, plant construction and component assembly.

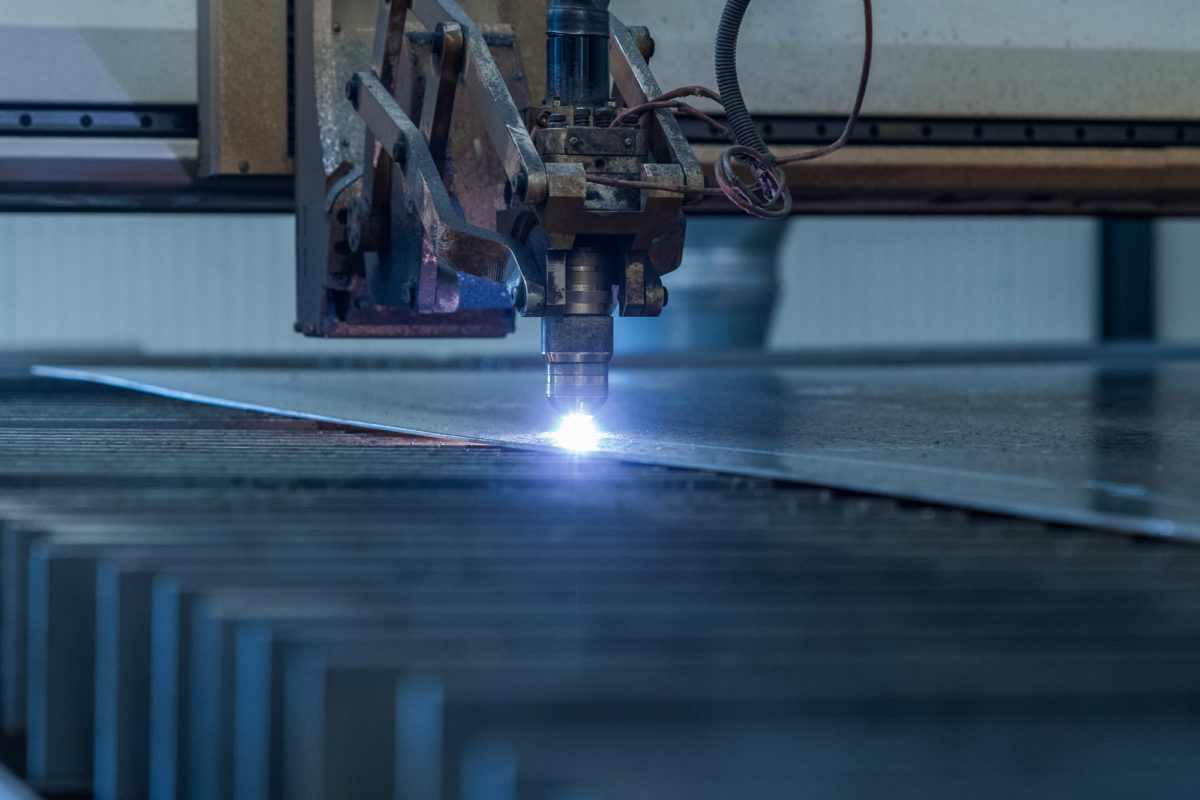

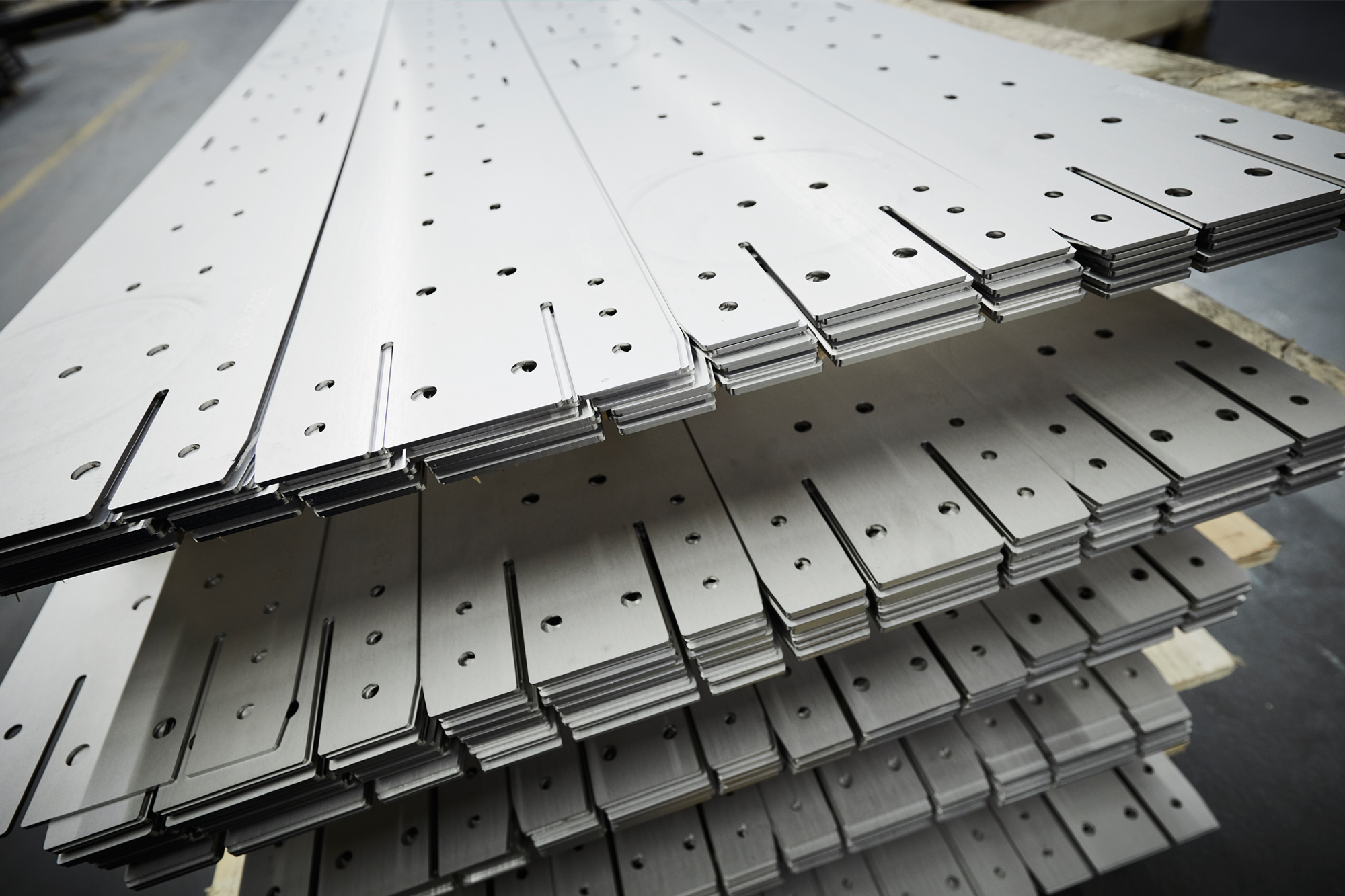

Metal processing Request nowSupplier production at the highest level

We deliver quality.

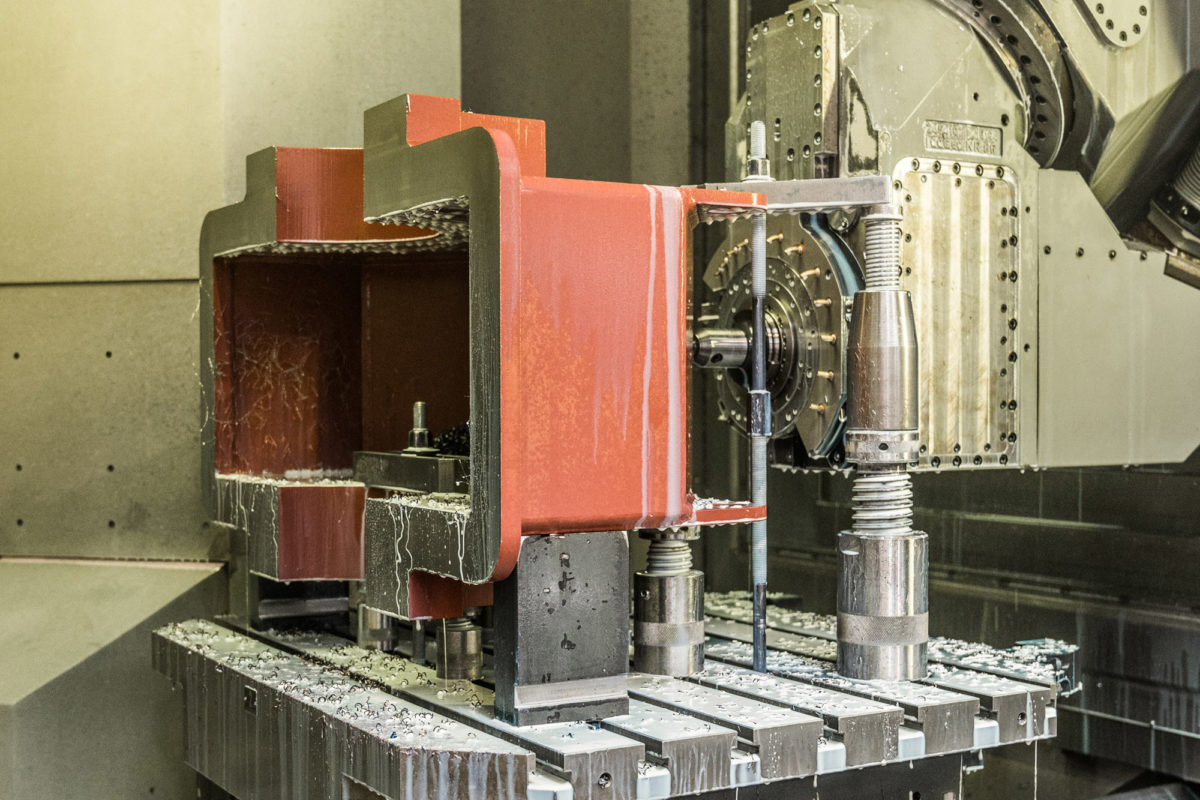

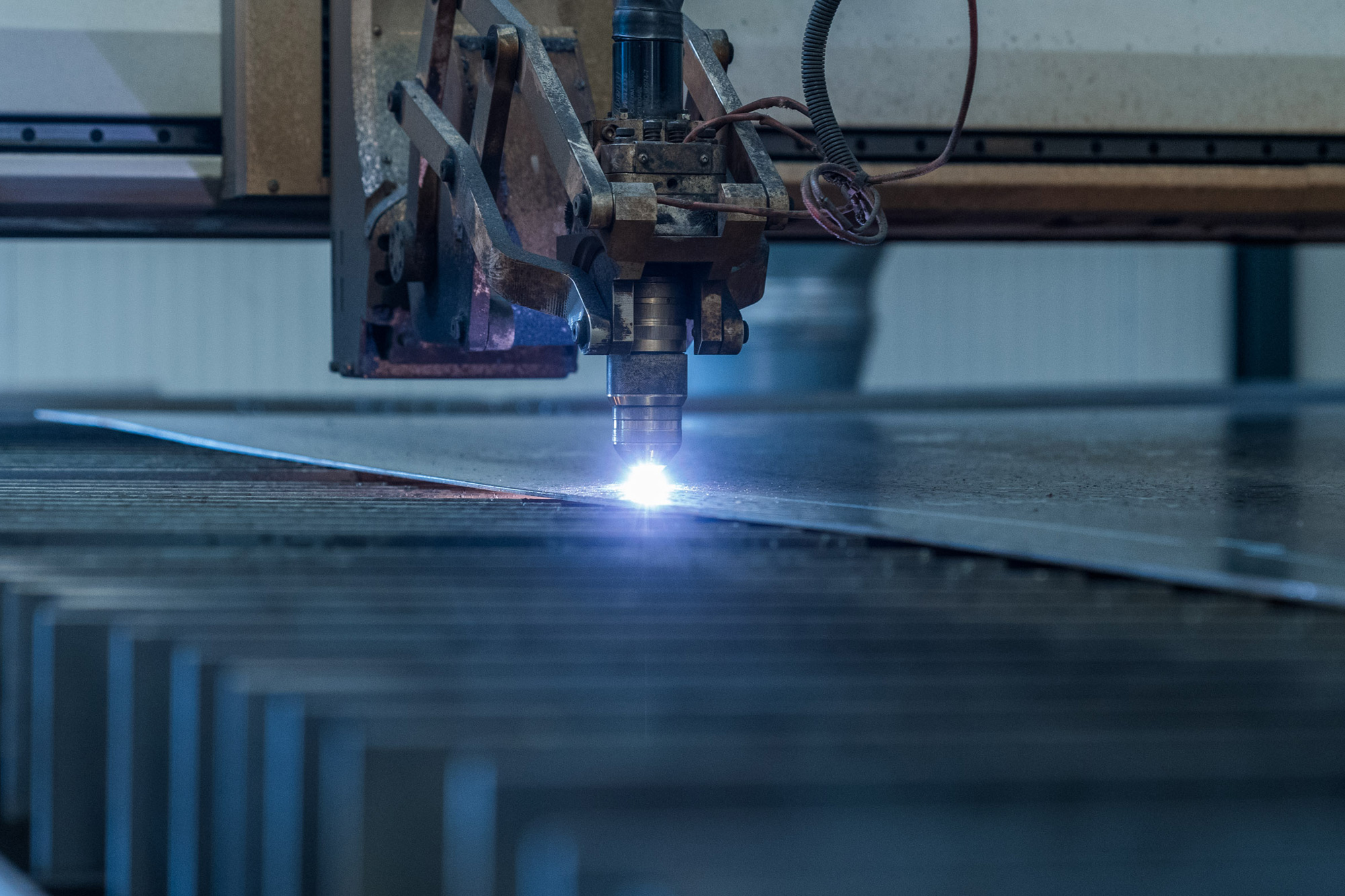

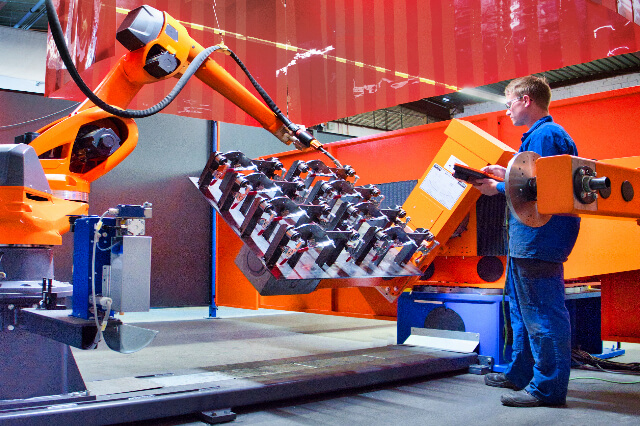

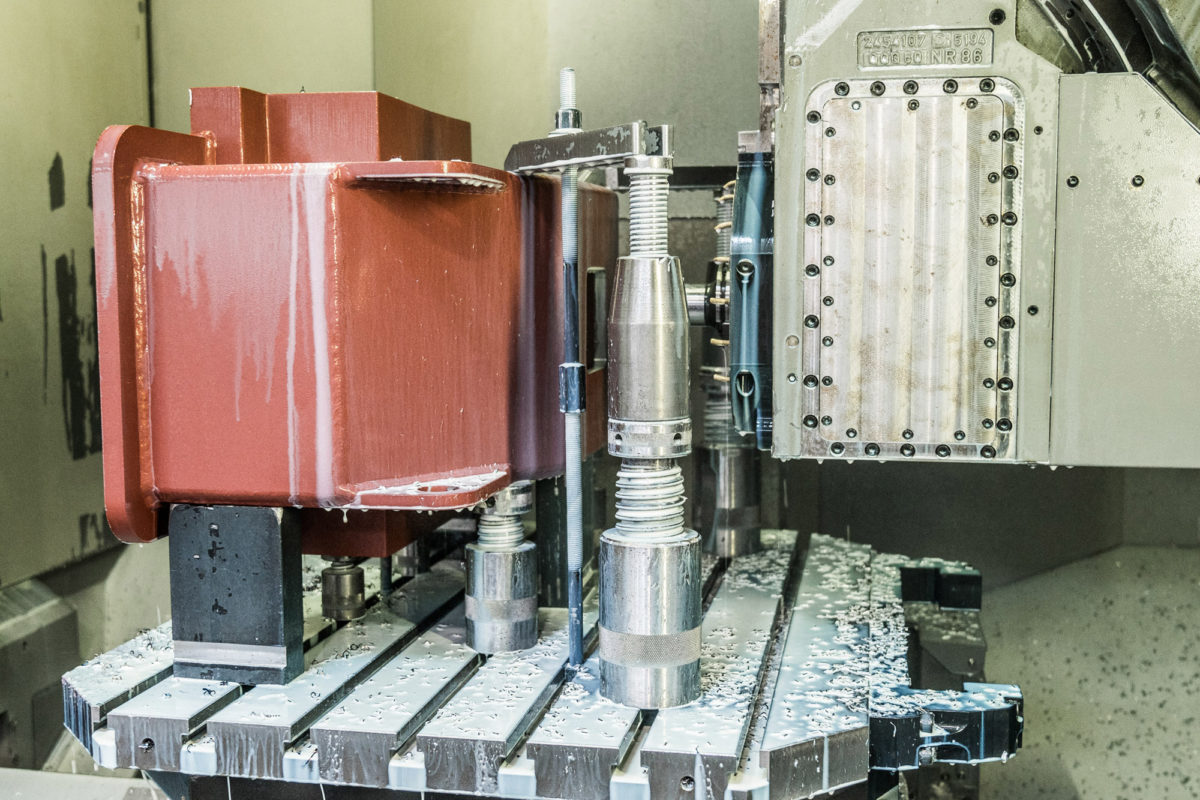

Whether laser parts, high-precision laser cutting, food conveyor screws and tanks made of stainless steel, complex welded components for rail vehicles, components welded by robots or precision parts manufactured to an accuracy of a thousandth of a millimeter that help to drive the energy transition high up in wind turbines – SPALECK manufactures to the highest quality and production standards.

Metal processing from A-Z

97 percent vertical integration

As a mechanical engineering company and supplier for metal processing, we offer you complete metal processing from a single source.

We produce welded assemblies with CNC machining ONESTOP for you.

To the precision parts supplier divisionExcellent!

Our manufacturing capabilities

Highly trained employees, state-of-the-art production capacities and a reliable order service are what we offer you!

We produce for our customers in three-shift operation. When can we welcome you?

Contact us

Mechanical engineering since 1869

EXPERIENCE

Over 150 years of experience as a machine manufacturer and decades of supply expertise in metal processing.

TERMINAL REVIEW

We take quality and adherence to deadlines very seriously.

COMPETENT PRICE

With over 500 employees, we are one of the leading suppliers. We pass on our size advantage to you through attractive prices.

FLEXIBLE

We offer our customers maximum flexibility and vertical integration.

TOP TRAINED

State-of-the-art production capacities.

Top-trained specialists.

This is SPALECK

Supplier for highly complex welded assemblies

Our day-to-day business

Whether tank construction, pressure equipment according to AD 2000,

load-bearing components for steel structures up to EXC3 or, for example, welded components for rail vehicles in accordance with DIN EN 15085-2, CL1:

We manufacture with the highest quality standards and the experience of more than 150 years of machine and plant construction(to our certificates).

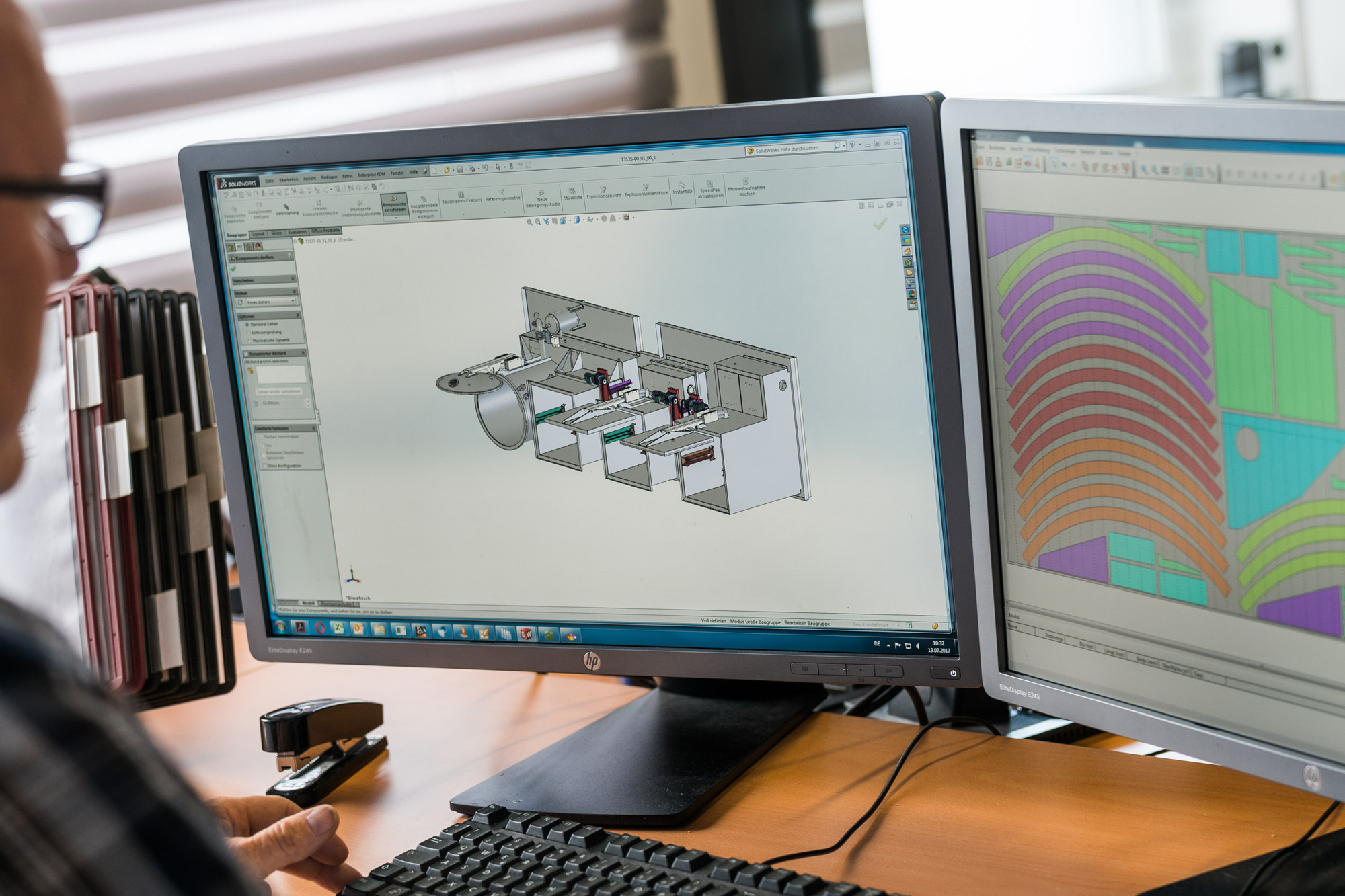

To the welding assemblies For robot weldingDesign and engineering included

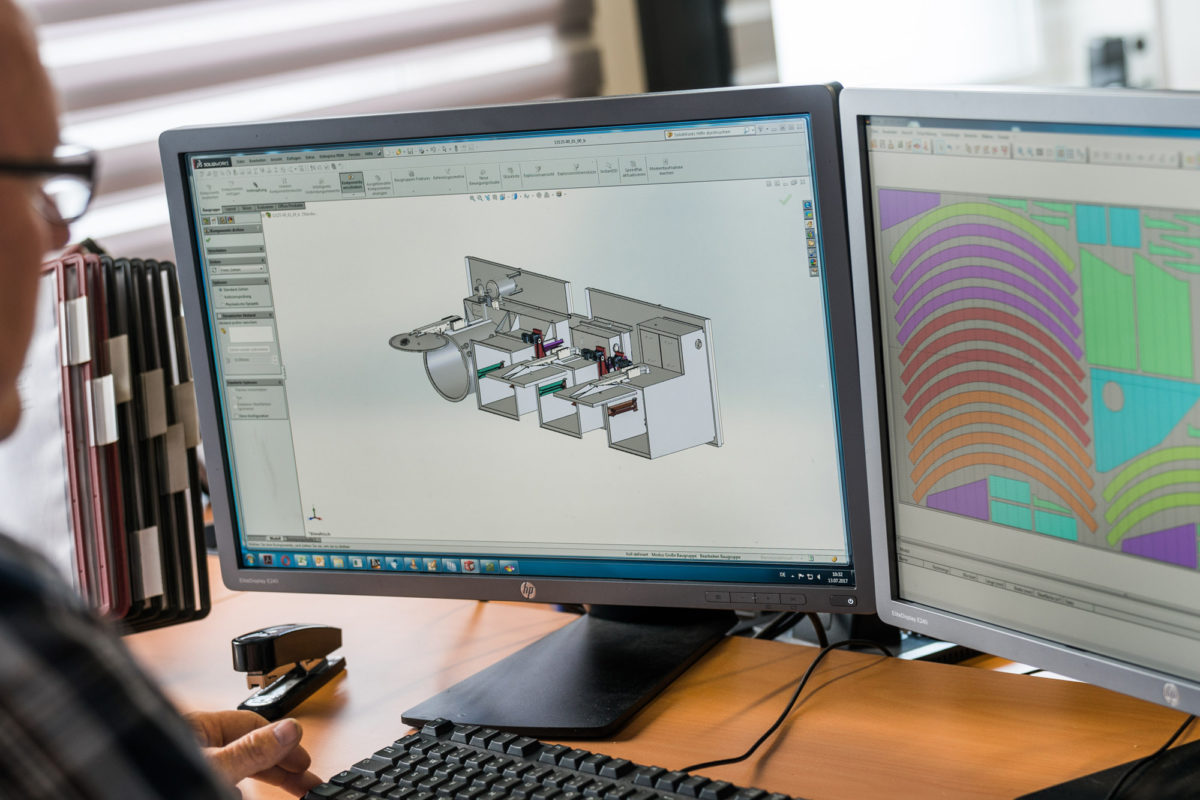

Product improvement & Design2Cost included

We have been building pioneering machines and machine components made by SPALECK for five generations.

We always incorporate this experience into our customers’ products. For example, our technicians work with your specialists to develop more cost-effective and better products or components.

And all this in addition to your production order.

Contact us

Metal contract manufacturer. Quality in series.

We manufacture for you

- Prototypes and individual pieces

- Small series up to 1,000 pieces/a

- Medium series up to 30,000 units/a

Our service

- Call-off orders

- Just in time delivery

- Warehousing & global logistics

Your material?

Always in stock!

On request with 3.1B certificate

The primary materials we use include

- Stainless steels

1.4016

1.4301 (V2A)

1.4307

1.4404

1.4571 (V4A)

1.4310 (spring steel) - Duplex steels

- Steel sheets

DC01

S235

S355 (QSTe380)

- Galvanized materials

DX51d - Wear-resistant sheet metal

1.8714 (Hadox) - Aluminum

AlMG3

AlMGSi05 - Special sheets

Weeping plates

FAL sheets

Brushed sheets

Ground sheet metal (K240)

3D optics (2R)

Facts and figures

Our locations in Germany, the USA and Romania

155

Years of experience

500

Employees

30000

m²

Production area

We are proud of this

Our customers

“As a quality supplier, SPALECK helps us very reliably to fulfill our quality promise.”

Apostore is a leading provider of warehouse automation systems for pharmacies.

We guarantee our customers “Leading Technology For Your Success”.

SPALECK has been manufacturing highly complex assemblies for us for years.

As a quality supplier, SPALECK helps us very reliably to fulfill our quality promise.

We see SPALECK as a partner with whom we can further expand our technology leadership:

The competent technical advice, the very high production quality and adherence to delivery dates are absolutely convincing.

In short: with the SPALECK team, we are shaping the future of our products.